Product

Lightweight Concrete

03. Soft ground

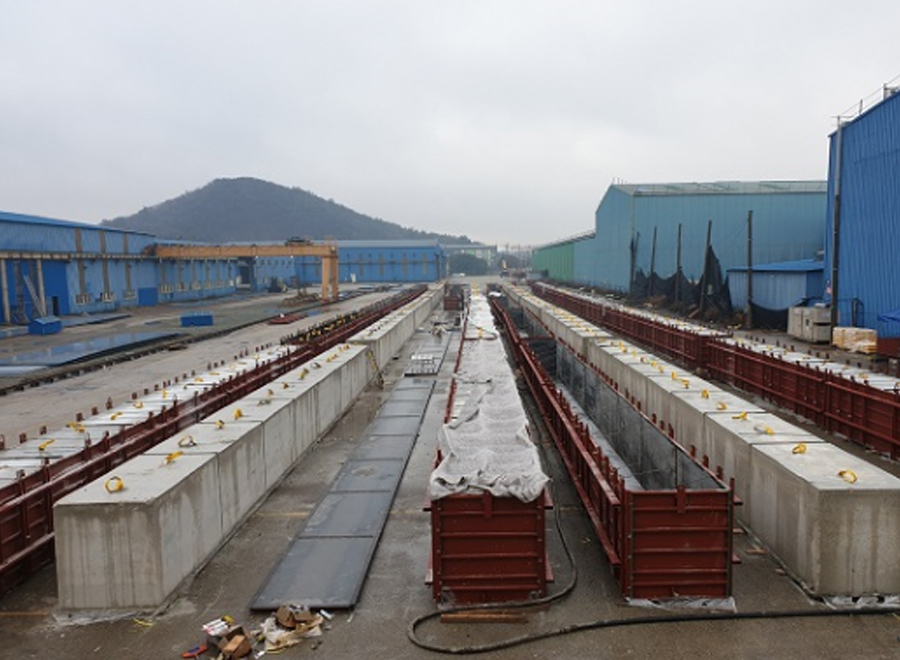

01. Formwork assembly

02. Batch plant installation

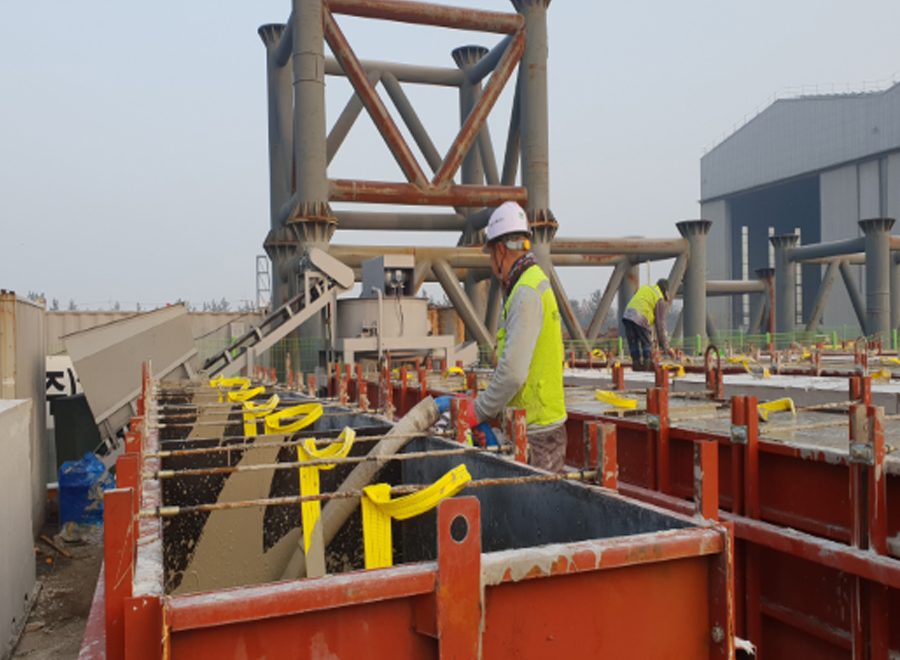

03. Placement

04. Curing

05. Formal disintegration

06. Block transportation

07. field arrival

08. Block Setting

09. Field interview

10. Block Setting

11. Blockage and site placement completed

| Identification | Lightweight Foamed Concrete Placement | Cellular Lightweight Mixed Soil |

|---|---|---|

| Comparison of sacrificial properties |

(Specifications: Cement: 0.32ton/m3) ㆍSpecific gravity: 0.6 ㆍStrength 1.0Mp (excellent load relief and durability) |

(Specification: Cement: 0.32ton/m3) ㆍWeight: 0.7 or higher ㆍStrength: 0.8Mp |

| Construct ability |

ㆍIt is relatively simple to process, so construction is quick and easy to

manage. ㆍIt is easy to install, dismantle and move by small plant operation,Minimize workspace occupancy. ㆍExcellent in curing speed and favorable for construction in winter. |

ㆍRelatively complex process. ㆍMaterial soil (deodorant), sate field is needed. ㆍInstallation of large scale plant and installation / repair of gypsum for screening of soil in site is necessary. |

| Quality Management |

ㆍHomogeneous quality is ensured because a certain standard material

is stirred. ㆍIt is possible to manage the construction joint by easy management of the installation height. |

ㆍIt is difficult to select the material soil (10mm or less, remove mud). ㆍIt is difficult to ensure homogeneity of material soil, ensuring homogeneous quality of finished product |

| Reason for selection |

ㆍLightweight foam concrete pouring method is relatively light in weight and high in strength, so it has excellent load reduction effect, endurance and durability ㆍThe product is homogeneous and excellent in mutual adhesion strength, so there is no fear of loss due to underground water stream, it is suitable to the requirements of the site and excellent in workability and air saving effect. It is judged that it is reasonable to change construction. ※ Example of change in construction method: "Incheon International Airport 2nd Passenger Office Building Connection Railway Corporation (Korea Railway Facilities Corporation)" In the underground reinforcement work on the upper railway connection box on site, During the construction, it is changed to lightweight foam concrete pouring method due to uncertainty of material strength and separation of materials. |

|